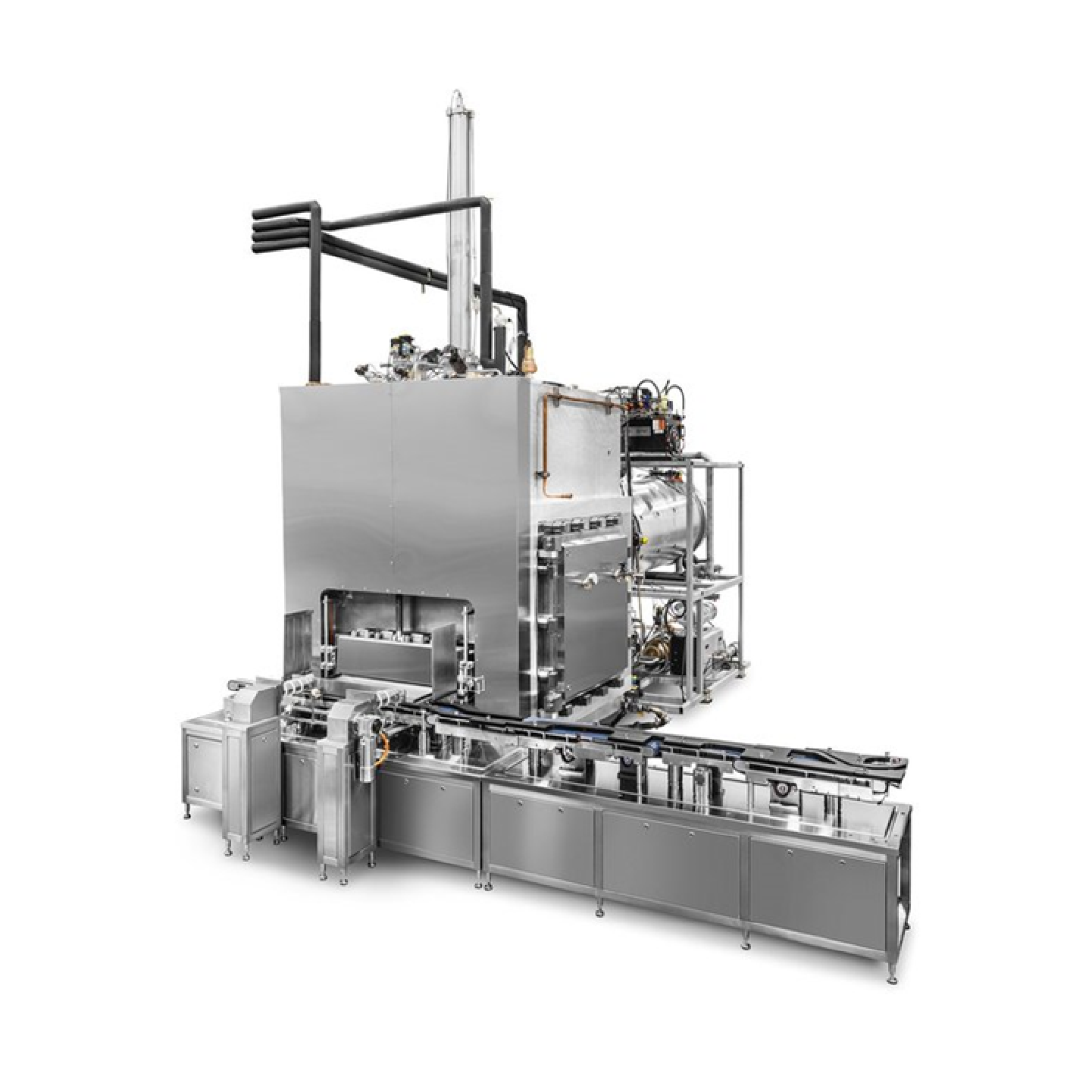

Lyophilized (Freeze Dryer) Machine

Lyophilizer or Freeze Dryer Machine equipped with Loading & Unloading Systems

Our Hull LyoConstellation™ S80, S100 and S130 Production Lyophilizers build on SP’s reputation as a pioneer of freeze-drying technologies. Equipped and controlled as a production system, the LyoConstellation offers a seamless approach to scale-up while being designed for line integration. If time is not on your side, rest assured that our lyophilizers are ready to order — for faster than average market delivery.

Built for demanding lyophilization needs — Each of our units can accommodate vials up to 100 mL. You can therefore develop the most aggressive of freeze-drying cycles safe in the knowledge that you’re using a lyophilizer that works with you.

State-of-the-art lyophilization technologies — To help you overcome the mounting challenges when scaling up your lyophilization processes for development, all Hull LyoConstellation™ Production Lyophilizers are compatible with our Line of Sight™ suite of scalable lyophilization tools that incorporate Process Analytical Technologies (PAT) to automate, control, and support the lyophilization process. This guarantees efficiency, quality and consistency throughout the entire fill-finish process.

SP’s Line of Sight PAT Tools:

LyoFlux® TDLAS

Let the data guide you! Measure water vapor mass flow with accuracy during freeze-drying

SMART™ Freeze Dryer Technology

No hesitation – get instant feedback on important product data including resistance, heat flow, and mass transfer

TEMPRIS® Wireless Sensors

Advanced wireless temperature monitoring for the highest quality product — on budget and on time

ControLyo® Nucleation Technology

Take control of your freeze-drying with cutting-edge nucleation technology — for precise control of the freezing point

Application Examples

• Therapeutic Proteins

• ADC Production for Clinical Trials

• Medium Batch Production for Compounding Pharmacies and Pharma, Including CMO and CRO

• Diagnostics

Features & Benefits

• Taking you from start to finish — ideal for cycle development and scale-up to stability, pilot and clinical batch production, through full aseptic production

• Technologies that ensure quality — full suite of PAT tools and technologies enables Line of Sight approach in cycle development and scale-up for simplified technology transfer, assuring product safety and quality in production

• Validation made easy — validation ports in chamber and condenser as standard, with full documentation package and support available

• Accurate end points — Pirani gauge and capacitance manometer as standard

• Full Steam in Place (SIP) & Clean in Place (CIP) execution, with manual/H2O2 option

• Isolator ready with auto locking doors

Designed for advanced aseptic pharmaceutical processes involving lyophilization, the SP Hull Freeze Dryer Loading and Unloading Systems – the RxR-36 Row-by-Row and the SALS-30 Semi-Automatic Freeze Dryer Loaders – are innovative, high-performance and flexible – reducing your overall processing times for improved productivity and greater cost efficiency.

Additional options allow you to integrate with the SP Hull LyoConstellation range of development, pilot, and production freeze dryers – for aseptic lyophilization that you can rely on.

• Easy decontamination

• Guaranteed sterility thanks to superior containment

• Compliant – all freeze dryer loading and unloading systems adhere to latest cGMP standards

Overview

We’re here to help you mitigate the risks associated with freeze dryer loading. Our loading and unloading systems ensure operator and product always remain protected, with minimal human intervention for the ultimate security. And with bridge and transfer plates that always operate within the aseptic environment, you can be sure that GMP standards are always adhered to. In addition, the loading and unloading system is designed to completely expose the surface during the decontamination process – for easy cleaning and effective sanitation.

Seamless integration – SP Hull Freeze Dryer Loading and Unloading Systems offer flexible solutions for small batch and high-speed applications and the option to integrate with the SP Hull LyoConstellation range of development, pilot, and production freeze dryers. A powerful freeze dryer range designed with aseptic operation in mind. When integrated with SP loading systems and SP filling lines, you get a powerful combination of best manufacturing freeze-drying practices, enabling you to move your product from development to commercialization, in a shorter timeframe. Two models are available.

SP Hull RxR-36 Row-by-Row Freeze Dryer Loader

• For full line vial applications

• Suitable for high-speed applications

• Loading speeds of up to 400 vials per minute

SP Hull SALS-30 Semi-Automatic Freeze Dryer Loader

• Narrow profile to replace manual freeze dryer loading

• Small to medium batch vial handling

• Loading speeds of up to 70 vials per minute

With help from our product portfolio experts and dedicated engineers, you can configure SP Hull Loading and Unloading Systems to meet your exact application needs. For more help, complete our “SP Technical & Applications Support” request form.

Features & Benefits

• Easy decontamination – designed to completely expose the surface during the decontamination process

• Reduced or zero operator intervention – only through glove ports to optimize GMP aspects of freeze dryer loading

• Fully compliant with latest cGMP standards – the bridge plate and transfer plate always operate within the aseptic space

• Ideal for containment and sterility – designed to protect product from operators to ensure sterility, and to contain potent products to protect operators

OUR CLIENTS